Independent Study Confirms AeroDynamic Benefit

May 9, 2025For Immediate Release

” … The pods have been shown to offer a simpler, lighter, less invasive, and cheaper alternative to the conventional drag-reducing devices mentioned in this report.”

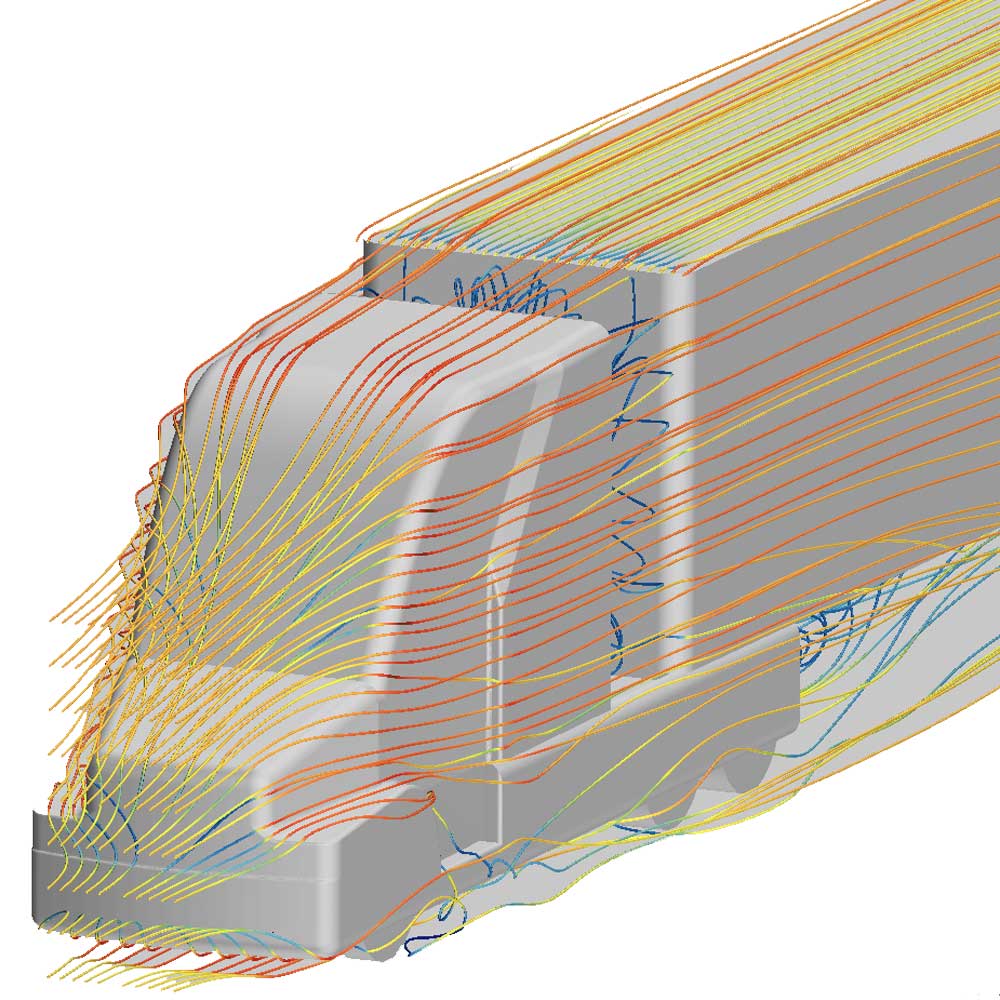

May 8, 2025, Ojai, California – We are proud to announce the findings of an independent study using advanced computational fluid dynamic (CFD) analysis to verify the efficacy of its patented technology to reduce vehicle aerodynamic drag. The technology is sold under its AeroHance product line. Reducing aerodynamic drag, axiomatically, results in fuel savings.

Marcus Boyd, School of Engineering, University of the West of England (UWE), Bristol, UK, conducted the independent study.

“The findings of this report display that AeroHance pods can offer an effective solution to the reduction of aerodynamic drag on Class 8 tractor-trailers, reducing the total drag force by up to 2.12% via the reduction in strength of vortices in the wake, thus leading to an increase in base pressure. At typical highway speeds, this corresponds to a fuel saving of approximately 1.38%.”

“For a 10-vehicle fleet of Class 8 tractor-trailers, this results in an annual saving of around $4136.49 for operations within the United States, or £7235.56 in the United Kingdom, with a reduction in CO2 emissions of roughly 11,005 kg.”

Savings are calculated at an average speed of 50 mph. This and previous studies on passenger vehicles showed aerodynamic improvement increases with speed. Traveling at 65 mph savings on a Class 8 tractor trailers increase to 1.65-1.7%, with annual savings closer to $5,000. This confirms an annual 25% return for a less than a $400 per truck investment.

“To the author’s knowledge, this report presents the most extensive study of flow control devices of this type applied to heavy vehicles. This assessment is based on the vast number of simulations conducted and the considerable amount of existing literature utilised to support analysis.”

White PaperAeroHance pods require no driver interaction and seamlessly integrate with existing fleet operations without modification or operational interference. The cost per truck is less than $400, providing an average return on investment in the first year after installation. The cost for passenger vehicles is less than $100 per car.

This new CFD study is consistent with and confirms on-the-road testing conducted by various fleets over 2 years of driving. The average fuel savings documented for tractor-trailers is 2.6%, and more than 6% for box delivery trucks and passenger vehicles.

The next generation in fluid flow technology

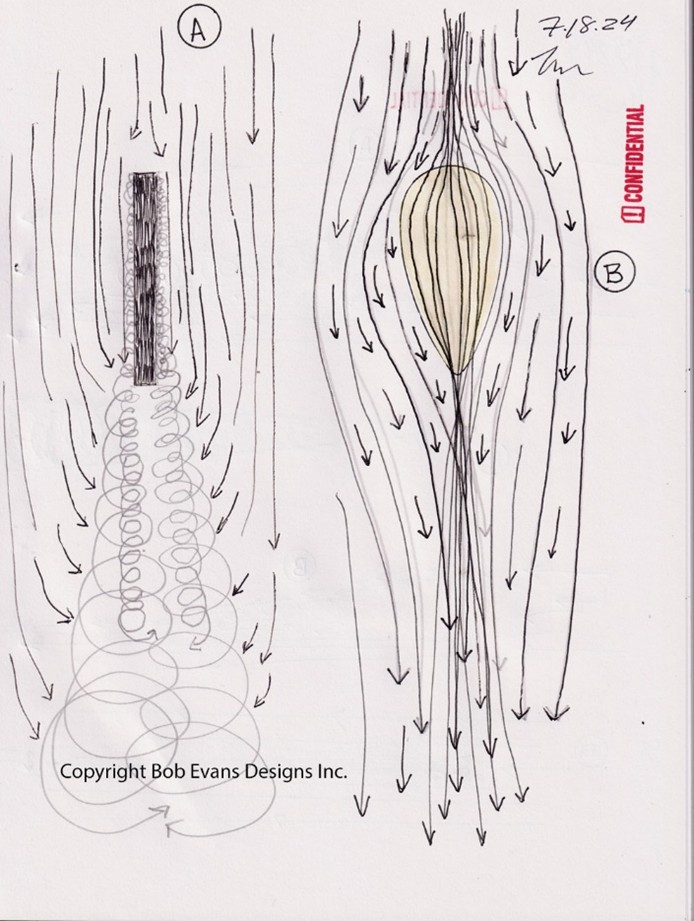

AeroHance Pods are proportionally shaped into a three-dimensional Barchistochrome Curve that accelerates air as it passes over the Pod to create the “Evans Flow,” named after the inventor of the patented pod shape. Forcing more air into the low-pressure area moves drag-inducing vortices farther behind and away from the vehicle. Evans Flow affects airflow in ways patently distinct from vortex generators, common to aviation.

Traditional Vortex Generators = A

- Function: Traditional VGs work by creating small vortices that energize the boundary layer, reducing flow separation and improving lift at high angles of attack.

- Mechanism: They spin the air to add energy to the slower-moving air near the surface, which helps maintain flow attachment.

Evans Flow = B

- Acceleration vs. Vortex: Instead of generating a vortex, accelerating air over a surface could aim to achieve similar or enhanced effects by:

- Increasing Airflow Velocity: The new shape accelerates the air over the Pod; this might help in reducing the boundary layer thickness or delaying its separation without necessarily creating a vortex.

- Instead of creating a low pressure between the counter rotating vortices – see diagram below – the Pod can force more air into the trailing range.

- Reducing Turbulence: An accelerated flow might be less turbulent than the vortex-induced flow, potentially offering a smoother transition over the control surface.

Technical support for this research was provided by Cape Horn Engineering | Yacht & Ship Design. Support by Bob Evans Designs, Inc. was limited to providing Pod geometry, suggested placement and our road test results as publicly posted at AeroHance.com With a per truck investment of <$400, no shell penetration, no downtime for installation or maintenance, AeroHance Pods promise 53′ fleet owners first year per ROI of 25%, with savings compounding thereafter. For shorter <28′ box delivery trucks road testing shows savings 3-5 times that amount. Previously conducted studies conclude the same for passenger vehicles.